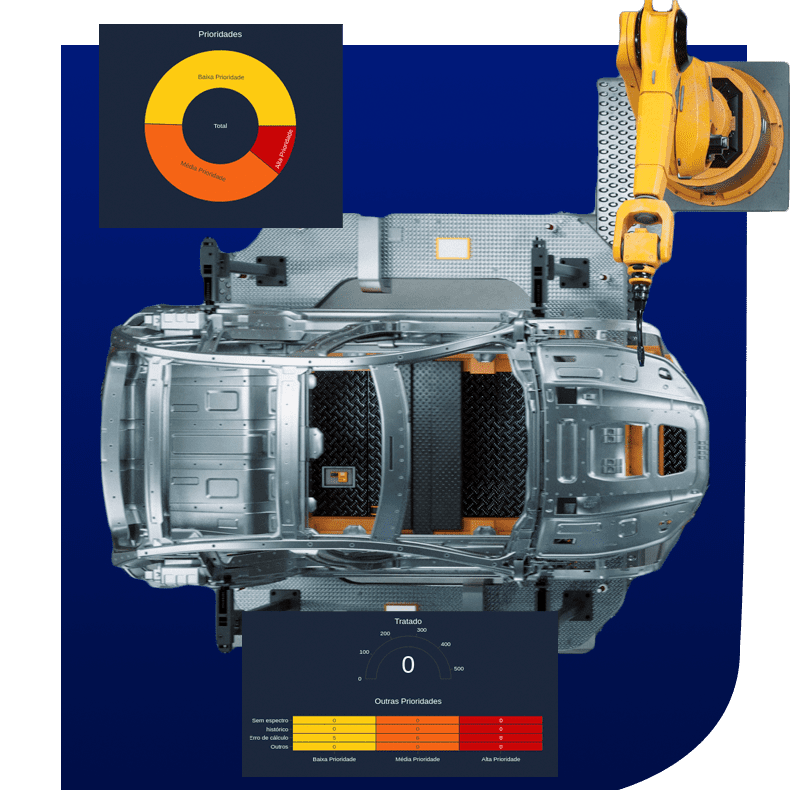

Converta dados em ativos mais eficientes.

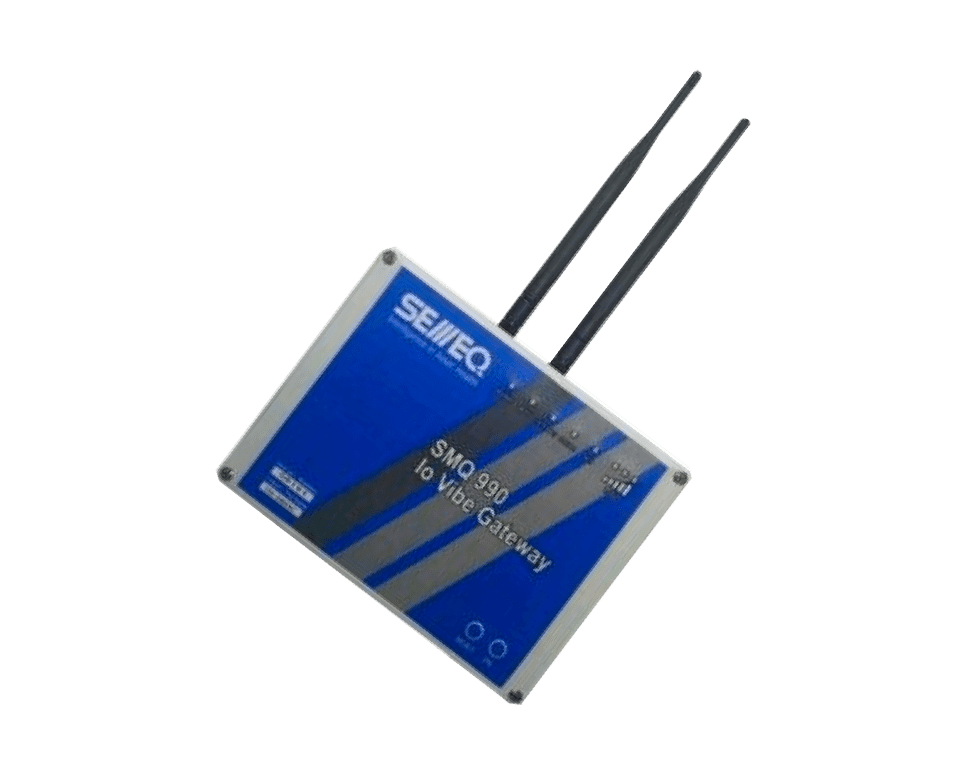

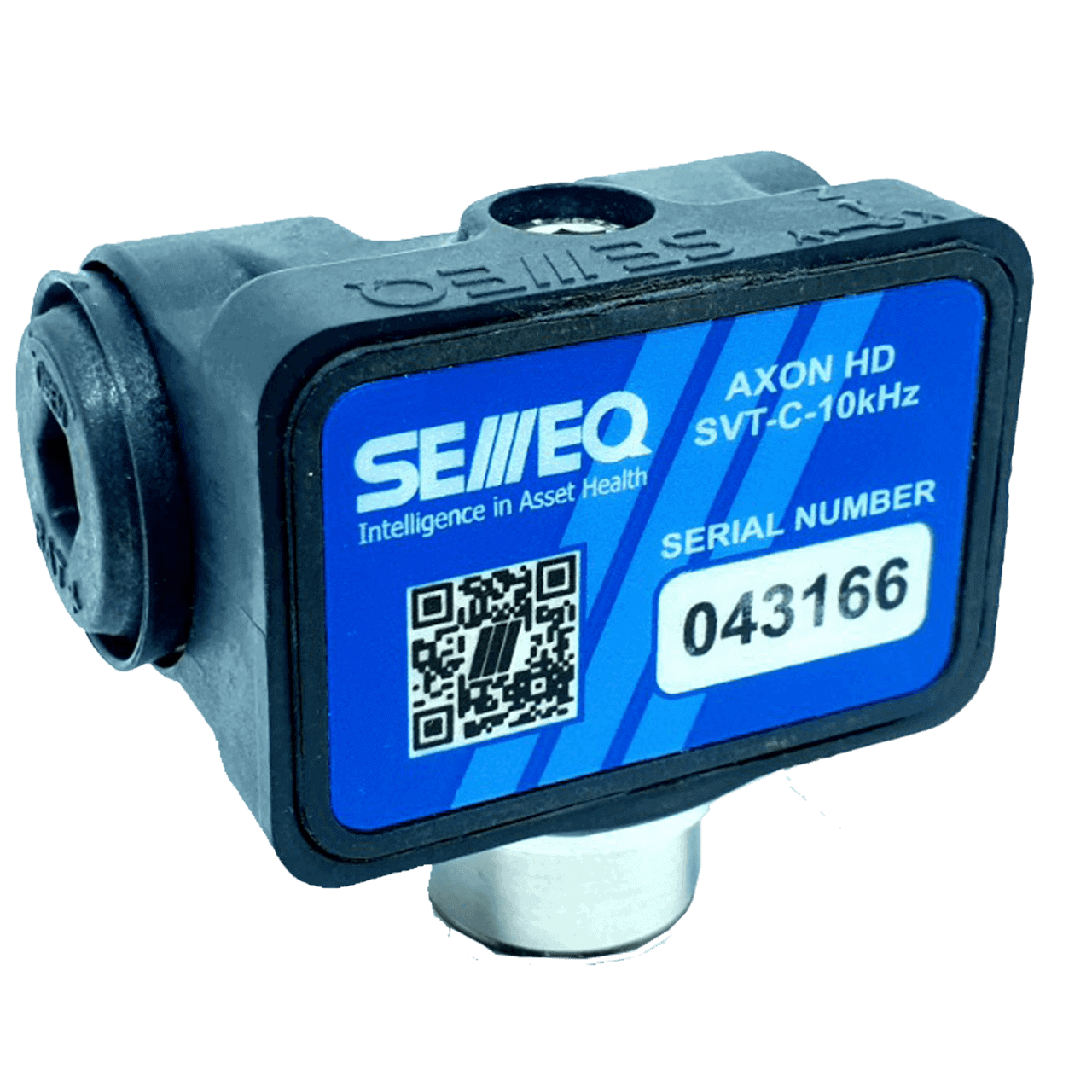

Ao transformar dados em informações, através dos nossos produtos e soluções, a Semeq gera insights para a tomada de decisão. Com uma equipe de P&D própria, desenvolvemos e fabricamos sensores wireless, coletores de dados, softwares de Inteligência Artificial e aplicativos dedicados à Manutenção Preditiva. São quase 30 anos de experiência. É a Semeq sempre saindo na frente, lançando as tendências do mercado e antecipando as necessidades dos nossos clientes. Não fique parado no tempo. Conheça já os nossos sensores wireless!