Parceria que potencializa resultados.

Inovation

Conectando tecnologia, informação e conhecimento.

Com 30 anos de mercado, dominamos todas as técnicas de Manutenção Preditiva. Estamos sempre nos atualizando e inovando. Fazemos análises de vibração, óleo, ultrassom, telemetria e muitas outras para saber como seus equipamentos estão e assim, evitar que eles falhem de forma inesperada. A vida da manutenção se transforma trazendo muito mais confiabilidade para os seus sistemas produtivos.

Informações Semeq

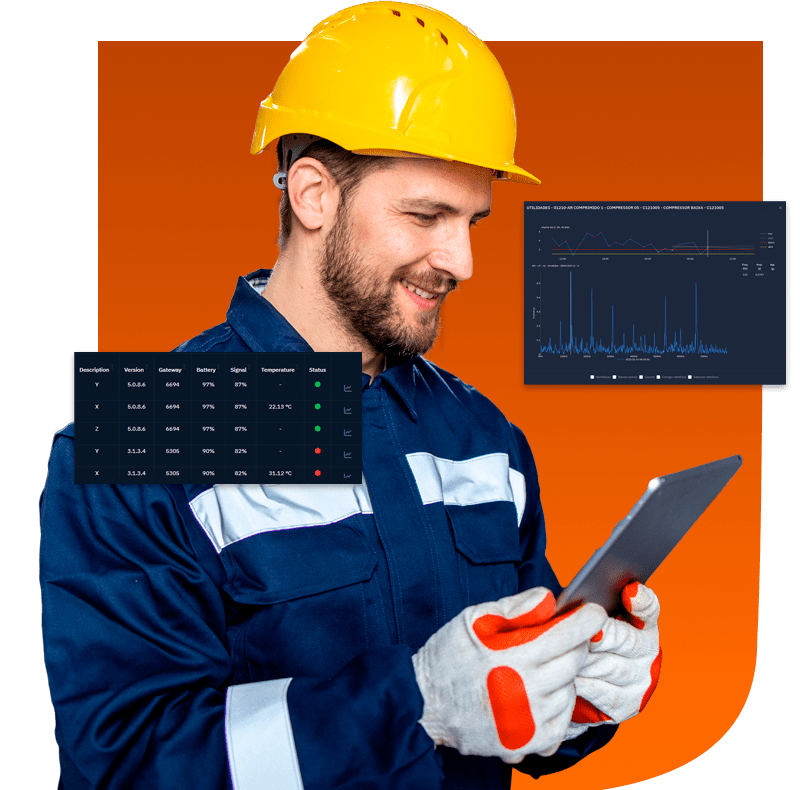

Coleta de Dados

Nossos sensores inteligentes para a Indústria 4.0 fornecem monitoramento mais preciso e maior previsibilidade de falhas.

Análise de Informação

Inteligência Artificial integra várias técnicas preditivas para realizar análises mais consistentes.

Gestão de Resultados

Algorítmos de analytics ajudam você a compreender o processo de falha de suas máquinas em busca de melhores indicadores técnicos e financeiros.

Mais de 36 países de atuação

+45Países

Clientes

Coca-Cola

ABInBev

Gerdau

JBS

Heinneken

BP

Ultragaz

Unilever

Bayer

Maxion Wheels

Solicite uma Apresentação

Preencha seus dados e envie uma mensagem para entrarmos em contato